Precision Turned Parts Manufacturer in China

Precision CNC Turned Parts Made Exactly to Your Specifications

Top-notch CNC Turning and Precision Turned Parts Manufacturer

Let us bring your product idea to life with our top-tier CNC turning services. We offer cost-effective CNC turning services without compromising turned parts’ quality, accuracy, and precision. Our facility features a variety of CNC turning machines of different sizes and capabilities to meet pretty much any manufacturing requirements. In addition, we have a team of highly qualified engineers and machinists who work with our quality control experts, ensuring that our products are always done right and satisfy the required standards and regulations. Our CNC turning services complement our other manufacturing capabilities, including injection molding, CNC milling, and 3D printing, providing our customers with a comprehensive manufacturing solution.

Why CNC Turning?

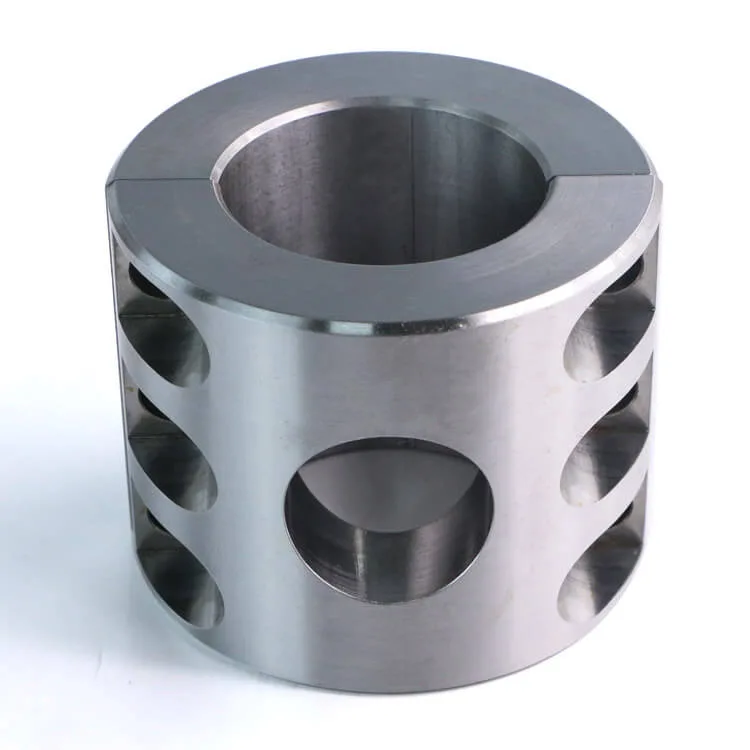

CNC turning is ideal for creating cylindrical shapes or parts that are symmetrical near their axis, for example, a chess pawn, bolts, rivets, ball bearings, and washers. CNC turning also solves some of the manufacturing challenges associated with CNC milling. For example, it allows you to create undercuts or relief grooves easily, whereas CNC milling machines require specialty cutting tools to achieve this. CNC turning machines also allow cutting operations to occur along 3-, 4-, or 5-axis, allowing you to perform taper turning, knurling, threading, and parting, among other operations. This subtractive manufacturing process is particularly suited for rapid prototyping and low volume production. Nevertheless, CNC turning can be used in tandem with CNC milling to create high-quality parts accurately while meeting tight tolerances.

CNC Precision Turned Parts Material Options

Metals

- Aluminum: 2021, 5052, 6061, 6063, 7075, etc.

- Steel: 303, 304, 316, stainless steel, tool steel, carbon steel, etc.

- Brass

- Copper

- Special alloys: Kovar, Invar, Inconel, Titanium, Mocu, etc.

Plastics

- POM

- PTFE

- PC

- PEEK

- PET

- PEI

- PA6

Look at Some Examples of Our Work

CNC Turning FAQs

The following parts are a good fit for lathe machining:

Rotary parts with high precision requirements.

Rotary parts with complex surface shapes.

Rotary parts with lateral machining.

Ultra-precision and ultra-low surface roughness parts.

Parts with special threads.

CNC turning is used for creating a variety of parts, including auto parts, knobs, tubes, gears, toy parts, flywheels, crankshafts, hubs & disc cams. It is most often used to manufacture CNC parts online for automotive, aerospace, medical, and other industries.

Heat treatments can be applied on precision CNC turned parts to improve their key properties such as hardness. Heat treatment can be applied to metal parts throughout the manufacturing process.

– Hardening: used to harden the material and make it stronger, also decreases the ductility.

– Annealing: heats metal parts to a very high temperature and then slowly cools to achieve the desired microstructure.

– Normalizing: used to relieve internal stresses that were created during machining service.

– Quenching: heating the metal to a very high temperature, followed by a rapid cooling step.

Applications of CNC Turning Services and Parts

AEROSPACE

INDUSTRY

AGRICULTURAL

INDUSTRY

AUTOMOTIVE

INDUSTRY

ELECTRONICS

INDUSTRY

FOOD

INDUSTRY

HIGH-TECH

INDUSTRY

MACHINE TOOL

INDUSTRY

MARINE

INDUSTRY

MEDICAL

INDUSTRY

MILITARY

INDUSTRY

SEMICONDUCTOR

INDUSTRY

SEMICONDUCTOR

INDUSTRY

Request a Quote for Turned Parts

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.