How does MG deal with mechanical keyboard shells with high surface requirements?

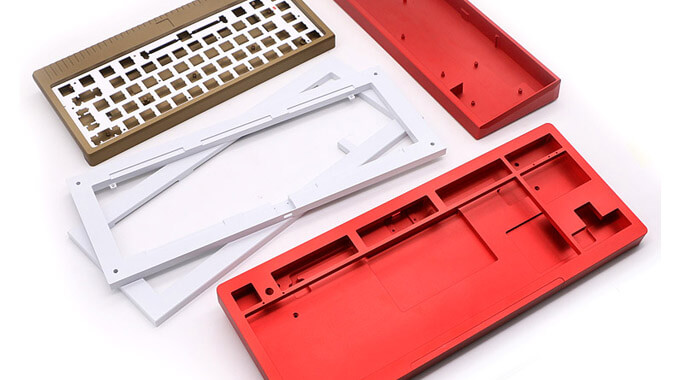

This kind of mechanical keyboard is not standard design, like GH60 GK61 , DIY TKL , 65, it is mainly sold to niche fans. Because it is taking the mid-to-high-end route, customers have strict requirements on the appearance and cannot have any defects on aluminum mechanical keyboard case. According to customer requirements by custom cnc machining, our engineers formulate corresponding special tools, fixtures and reasonable tool paths, and finally meet the customer’s quality requirements.

Raw materials

In order to make a high-end aluminum shell with high surface quality, like an Apple mobile phone, we must first start with materials selection. Among the aluminum raw materials, AL6061-T6 and AL6063-T6 are relatively cheap, and there are new materials and secondary materials from the material level. Because the surface needs to be sandblasted by 200# grit, AL6063 has higher aluminum content than AL6061, so AL6063 is the best choice, and a high-quality surface can be obtained.

CNC Machining mechanical keyboard case

For parts with large volume and long milling time, during the milling adjustment stage, our engineers changed the 20 flat cutters to 20 milling cutters, which increased the Z-axis feed rate and increased the efficiency by 30%. In order to have a perfect surface quality and reduce the surface machine marks and joint marks, our programmers have reduced the joint number, and made slight adjustments to the R angle, and used PCD tool to mill at one time.

Semi-finished products after cnc machining

A good semi-finished product is a prerequisite for a good surface treatment, so doing the last process of the semi-finished product is also very important. Before sending to anodizing, our operators will manually use 400# sponge to clean the sharp corners to prevent it being smoothed after oxidation, So the anodizing layer will fall off. For the semi-finished parts, we will clean them with clean pure water once to prevent the cutting fluid causes corrosion, resulting in blisters after anodizing.

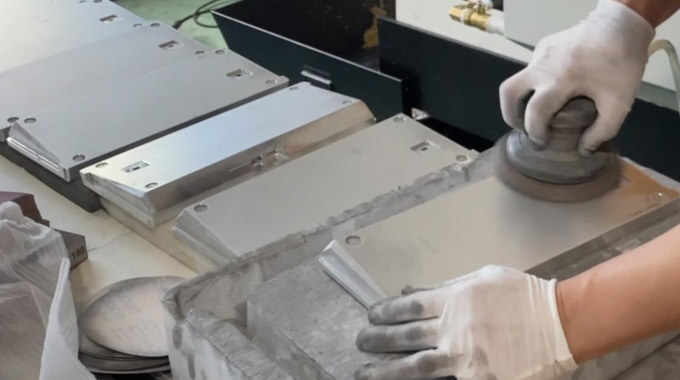

Polishing

For the semi-finished mechanical keyboard case that will be painted and electrophoresed, we will increase the manual polishing, the purpose is to increase the adhesion after the surface treatment.

Finished product after anodizing

No comment