How to process difficult 5-axis cnc machining petrochemical connectors by dismantling process, saving materials and combining 2+3 methods and reduce the cost to 20%?

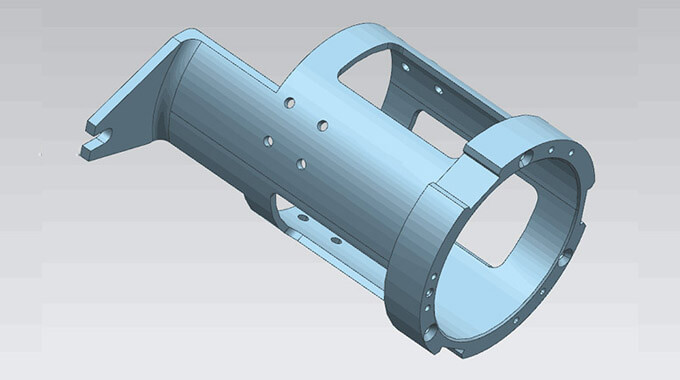

Our engineers conduct a process review according to the customer’s drawings. During the review, it is found that it is an irregular eccentric shaped part. According to the traditional processing method, it can only be produced by a 5-axis machine, and the material that needs to be purchased must be twice the outer diameter of the part. . The processing area is large, the time is long, and materials are wasted.

Based on the special product and the above reasons, CNC Machining processing cost is too high, our engineering decided to change the method.

| Item | Original processing method | Existing processing methods |

| Processing methods | Direct 5-axis machining | Design extruded profile drawing according to prototype |

| Order materials according to drawings | ||

| Machining the first process with a CNC lathe | ||

| After the fixture is installed, place it on the 3+2 machine for processing | ||

| Pros and cons | Long processing time | Save materials and reduce processing time, saving 20% of costs |

Manufacturing processes

CNC machining is to perform CNC machining according to the benchmark size of lathe machining.

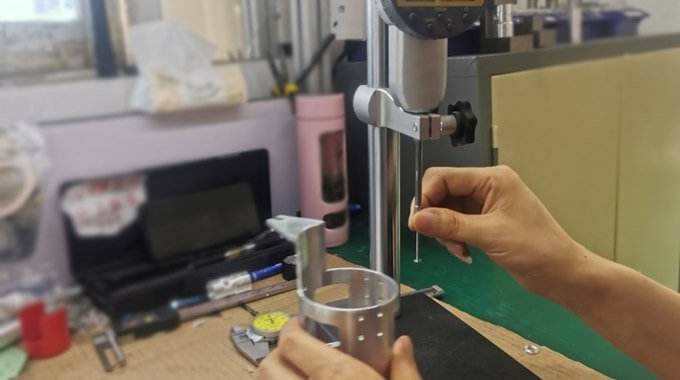

Tolerance detection

Various inspections are carried out according to customer requirements. We carry out first piece inspection and on-line inspection for each size during the production process according to the requirements of the customer’s drawings.

Package

No comment